Imagine you’re in a situation where you need a pump that can handle liquids with ease, whether it’s water, chemicals, or even food products. You might wonder what makes diaphragm pumps the go-to solution for such diverse applications.

Understanding how diaphragm pumps work could be the key to unlocking greater efficiency and reliability in your processes. As you dive into the world of diaphragm pumps, you’ll discover the magic behind their operation, the benefits they offer, and the reasons why they’re indispensable in various industries.

This knowledge could transform your approach to handling liquids, making your tasks simpler and more effective. Get ready to explore how these pumps can revolutionize your work, providing you with insights that are both fascinating and practical.

Principles Of Diaphragm Pumps

Diaphragm pumps move liquids using a flexible diaphragm. The diaphragm creates pressure when it moves. This pressure pushes the liquid through the pump. Liquid moves in and out of the pump. Valves control this movement.

Diaphragm pumps can handle thick liquids. They also manage dirty liquids well. These pumps are often used in industries like chemical and food. They do not need electricity to work. This makes them safe in dangerous areas.

Air pressure powers many diaphragm pumps. This makes them useful in many places. They are strong and can last a long time. Easy maintenance is another key feature. These pumps are simple to clean and fix.

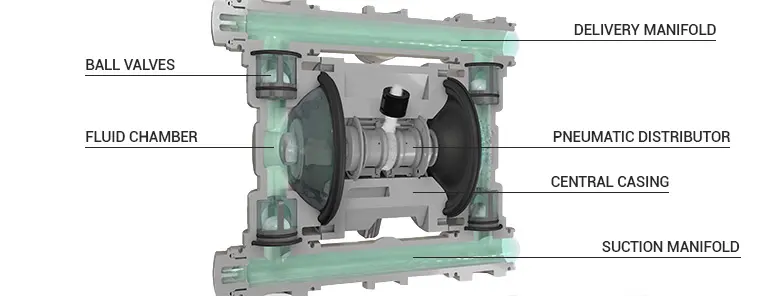

Components And Structure

The diaphragm is a key part of the pump. It moves to push the liquid. Materials like rubber or Teflon are often used. Rubber is flexible. Teflon is strong and resists chemicals. The choice depends on the liquid being pumped. A good diaphragm lasts long. It handles pressure and resists wear.

The pump casing holds everything together. It keeps the liquid inside. Metal and plastic are common materials. Metal is strong and used for heavy-duty jobs. Plastic is light and good for smaller tasks. The casing must be tight. It prevents leaks and protects the parts inside.

Valves control the liquid’s direction. They open and close as needed. Seals prevent leaks. Both are crucial for smooth operation. Valves are often made of metal or plastic. Seals are usually rubber. A good seal stops liquid from escaping. This keeps the pump working well.

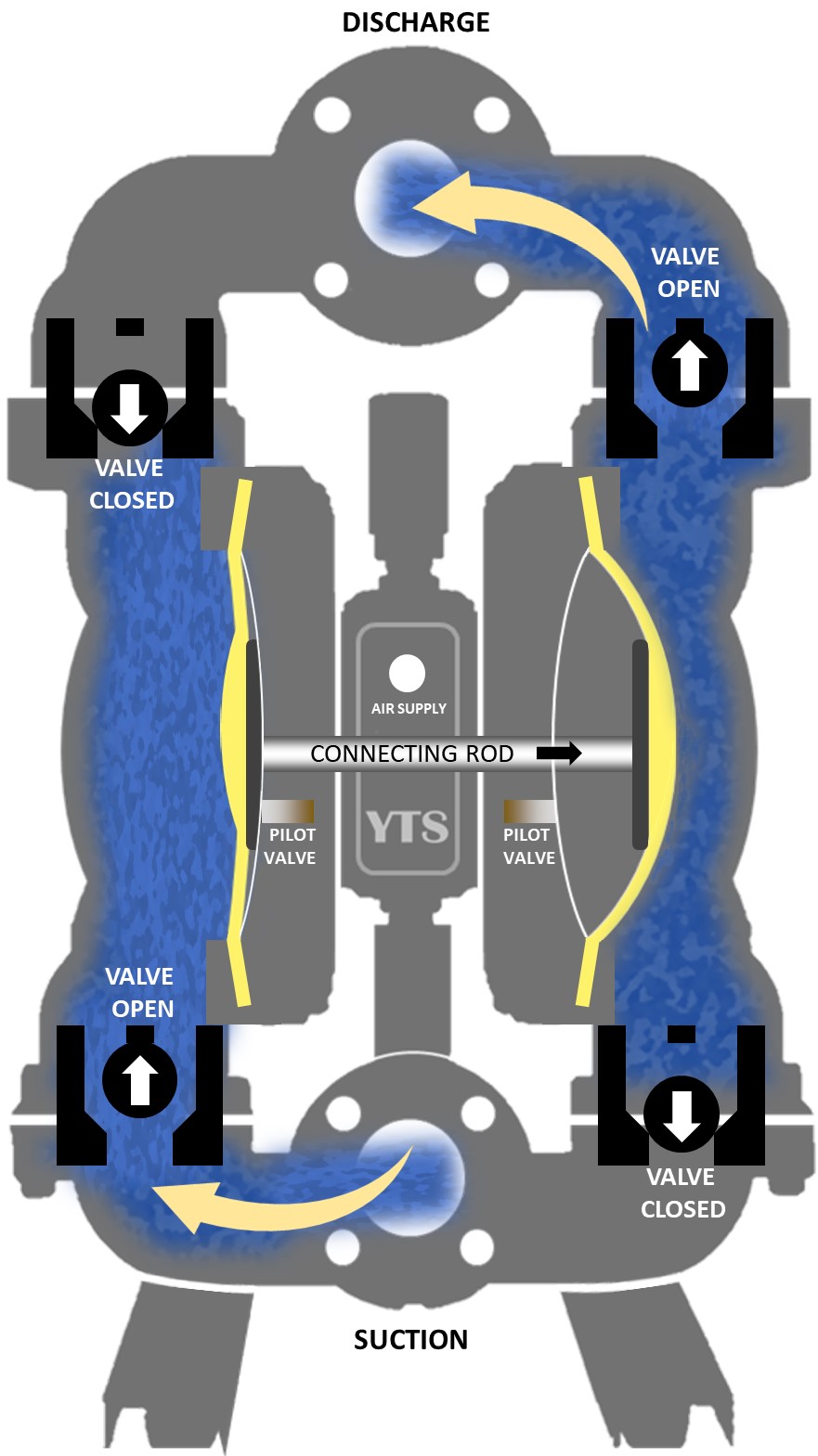

Mechanics Of Operation

Diaphragm pumps use a flexible diaphragm to move liquids. During the suction cycle, the diaphragm pulls back. This creates a vacuum in the pump. Liquid is then drawn into the pump chamber. In the discharge cycle, the diaphragm pushes forward. This action forces the liquid out. These pumps can handle thick liquids. They can even pump slurries with ease.

Check valves are very important. They control the flow of liquid. One valve allows liquid in, and the other lets it out. Check valves prevent liquid from going back. This ensures the pump works correctly. Without them, the pump will not work well. They keep the process smooth and efficient.

Types Of Diaphragm Pumps

Air-operated diaphragm pumps use compressed air to move liquids. Air pressure pushes the diaphragm, creating a pumping action. These pumps work well with hazardous liquids. They can handle viscous or abrasive materials. Safety is a key feature. No electricity is needed, reducing spark risks. Reliable in tough conditions. Versatile for many industries.

Hydraulic diaphragm pumps use hydraulic fluid for power. The diaphragm moves by fluid pressure. These pumps offer precise control. Useful for chemical and oil industries. High pressure capabilities make them strong. They can pump corrosive liquids safely. Durable design ensures long life. Efficient in energy use.

Electric diaphragm pumps run with electric motors. Electricity moves the diaphragm, pumping liquids. Good for clean environments. Quiet operation is a plus. Easy to control with switches. They work best with non-flammable liquids. Compact size fits small spaces. Ideal for home or small industry use.

Fluid Dynamics In Diaphragm Pumps

Diaphragm pumps use a flexible membrane to move fluid. The membrane creates unique flow patterns. As the diaphragm moves, it pushes and pulls liquid. This movement causes fluid to move in a specific way. Fluid can move smoothly or in waves. The pump controls how the liquid flows. This control helps in many applications. Different flow patterns suit different tasks. Understanding flow patterns is crucial. It ensures effective pump operation.

Diaphragm pumps handle various pressure variations. Pressure changes occur inside the pump. The diaphragm’s movement affects pressure levels. As the diaphragm expands, pressure increases. When it contracts, pressure decreases. These changes are vital for pump performance. They help move liquids efficiently. Maintaining proper pressure is essential. It ensures the pump works well. Understanding these variations is key. It helps in choosing the right pump for a job.

Applications Across Industries

Diaphragm pumps move chemicals safely. They handle acids and alkalis well. These pumps work in tough environments. They resist corrosion. They also prevent leaks. In this way, they protect workers and the environment. They are easy to clean. This makes them great for changing tasks.

Diaphragm pumps help clean water. They add chemicals to water like chlorine. They also remove waste. These pumps work quietly. They save energy too. Small pumps fit in tight spaces. They last a long time with little care.

Pumps keep food and drinks safe. They handle sauces, juices, and dough. The pumps are easy to clean. This keeps food pure. They also work well with thick liquids. Many food factories use them. They follow health rules.

Advantages And Limitations

Diaphragm pumps are efficient for moving liquids. They use less energy than other pumps. This saves money. Many industries prefer these pumps. They work well with different liquids. Some pumps need lots of care. Diaphragm pumps need less. This saves on maintenance costs. They are not perfect. Sometimes, they work slower. For big jobs, this is a problem.

Maintaining diaphragm pumps is easy. They have few moving parts. This means less wear and tear. Regular checks are important. Small issues can become big. Changing parts is simple. Some parts can be hard to find. Always keep spare parts. Proper care extends the pump’s life. This saves money in the long run.

Future Trends And Innovations

Diaphragm pumps operate by moving a flexible diaphragm to create a vacuum, drawing in and pushing out fluid. This mechanism ensures efficient fluid transfer without leakage. As technology progresses, new materials and designs enhance pump durability and performance.

Technological Advancements

Diaphragm pumps are getting smarter. Sensors are added to improve performance. These sensors help in real-time monitoring. They ensure the pump works smoothly. Automation is another trend. It makes pumps run on their own. This reduces the need for human help. Smart apps can now control these pumps. Users can change settings from anywhere. This makes pumps more user-friendly.

Sustainability Efforts

Diaphragm pumps are becoming greener. Eco-friendly materials are now used to make them. This helps in reducing waste. Many pumps now use less energy. This saves power and money. Recyclable parts are another feature. They help in reducing the carbon footprint. These changes make pumps better for the earth.

Frequently Asked Questions

What Is A Diaphragm Pump Used For?

Diaphragm pumps are versatile and used for transferring various fluids. They handle abrasive, corrosive, and viscous liquids efficiently. Common applications include chemical processing, food and beverage, and wastewater treatment. Their ability to handle solids makes them ideal for industrial use.

They are also used in medical devices and laboratories.

How Does A Diaphragm Pump Operate?

A diaphragm pump operates using a reciprocating action. This action involves a flexible diaphragm moving back and forth. The movement creates a vacuum that draws in fluid through an inlet valve. The fluid is then pushed out through an outlet valve.

This simple mechanism ensures efficient fluid transfer.

What Are The Advantages Of Diaphragm Pumps?

Diaphragm pumps offer several advantages. They are self-priming and can handle high-viscosity fluids. They are also suitable for hazardous and corrosive liquids. These pumps provide a leak-free operation due to their sealed design. Additionally, they are low maintenance and have a long service life.

Can Diaphragm Pumps Handle Solids?

Yes, diaphragm pumps can handle solids effectively. They are designed to transfer fluids containing suspended solids. The pump’s flexible diaphragm allows it to move solids without causing damage. This makes them suitable for sludge, slurry, and other solid-laden liquids. Their ability to handle solids is a key feature.

Conclusion

Diaphragm pumps are efficient and versatile for many industries. They handle different fluids with ease. Their simple design ensures reliability and easy maintenance. These pumps work well in harsh conditions, making them a popular choice. Understanding their operation helps in selecting the right pump.

Proper use extends their lifespan and enhances performance. Diaphragm pumps offer a practical solution for various applications. They are cost-effective and environmentally friendly. With these benefits, they continue to be a trusted option for fluid transfer. Whether for industrial or commercial needs, diaphragm pumps prove valuable.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Diaphragm Pump Cost Comparison: Affordable Options Unveiled

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance