Are you considering investing in a diaphragm pump but unsure about the cost implications? You’re not alone.

Making the right choice involves more than just looking at the price tag. It’s about balancing quality, efficiency, and long-term benefits. Imagine finding the perfect pump that not only fits your budget but also boosts your operational efficiency. This article is designed to guide you through a cost comparison of diaphragm pumps, providing insights that will empower you to make a smarter purchase decision.

Dive in to discover how you can optimize your investment and avoid common pitfalls. Don’t let uncertainty hold you back; clarity is just a few scrolls away.

Diaphragm Pump Basics

Diaphragm pumps are used to move liquids. They are important in many industries. These pumps are known for their reliability and durability. A diaphragm pump uses a flexible membrane to pump. It creates a vacuum to draw fluid in. Then it pushes it out. This pump type can handle viscous liquids and slurries. They are also suitable for chemicals and abrasive materials. The cost of diaphragm pumps varies. It depends on size and material. Some are affordable for small projects. Others cost more for heavy-duty use. Choosing the right pump is key. It ensures you get the best performance. Always consider maintenance and energy costs too.

Key Factors Influencing Cost

Diaphragm pump costs depend on factors like material, brand, and size. Material choice impacts durability and price. Brand reputation often influences cost due to perceived quality. Size determines capacity and cost, affecting overall expenditure. Comparing these aspects helps in finding the best value.

Material Selection

Choosing the right materialaffects pump cost. Metal pumpsare often more expensive. They last longer and handle tough tasks. Plastic pumpscost less. They are lighter and better for simple jobs. Chemical resistancematters too. Some materials resist chemicals better. This choice impacts cost.

Pump Capacity

Capacityis a key factor. Small pumps cost less. They handle low volumetasks. Big pumps are pricier. They manage high volumejobs. Capacity needs affect the price. Choose based on your needs. This helps control costs.

Brand Reputation

Brand reputationinfluences cost. Known brands often charge more. They offer reliable products. Lesser-known brands might be cheaper. They can be risky. Customer reviews help decide. Brand choice impacts cost and trust.

Affordable Brands And Models

Several brands offer affordable diaphragm pumps. These pumps are good for small jobs. Brands like ARO and Graco are known for low-cost models. They provide reliable performance without breaking the bank. Ingersoll Rand is another brand to consider. Their models are both efficient and cost-effective.

| Feature | Low Price Range | High Price Range |

|---|---|---|

| Flow Rate | 5-20 GPM | 20-100 GPM |

| Material | Plastic | Stainless Steel |

| Pressure | 50-100 PSI | 100-200 PSI |

Cheaper models have fewer features. They are often made of plastic. High-end pumps are made of stainless steel. This makes them last longer. They handle more pressure and flow.

Maintenance And Operating Costs

Diaphragm pumps are known for their strong build. This makes them last a long time. Less time is spent on repairs. This means more savings. Regular checks keep them working well. Parts are easy to find. This makes fixes quick. No special tools needed. Simple care keeps them running smoothly.

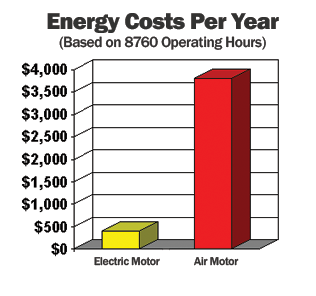

These pumps use less energy. This saves money on bills. They work well with low power. Good for the environment. Less energy means less cost. They stay cool while working. No overheating issues. This adds to their life span. They help in reducing carbon footprints.

Cost-effective Applications

Diaphragm pumpsoffer great value in many industries. They are used in food processing, where safe material handling is key. In paint production, these pumps ensure smooth flow without clogs. Agriculture benefits from affordable pumps for spraying and irrigation needs. They are also essential in the chemical industry, transporting liquids safely. Water treatment plants use them for cleaning and filtration. Their cost-saving design makes them a popular choice. These pumps help industries save time and money.

In a small paint factory, affordable pumps improved production speed. A farmer used these pumps to water crops efficiently. Chemical firms found them ideal for moving sensitive liquids. In a food plant, pumps helped transport sauces safely. A textile company used them to dye fabrics evenly. These examples show the real-world benefits of diaphragm pumps. They prove that cost-effective solutions work.

Future Trends In Diaphragm Pump Pricing

New technology is changing diaphragm pumps. Smart sensors can now monitor pumps. They tell when a pump needs care. This helps keep pumps working longer. Energy-efficient designs are also popular now. These designs save money over time. They use less power. This is good for the environment and your wallet.

Many factors affect pump prices. Global demand is a big one. When more people want pumps, prices can rise. Raw material costs also matter. If materials cost more, pumps cost more too. Companies try to keep prices fair. They want to sell more pumps. Competition between companies can help keep prices down.

Frequently Asked Questions

What Factors Influence Diaphragm Pump Cost?

Diaphragm pump cost is influenced by size, material, and brand. Larger pumps typically cost more than smaller ones. Materials like stainless steel are more expensive than plastic. Additionally, well-known brands might charge a premium due to their reputation for quality and reliability.

How Do Diaphragm Pumps Compare To Other Pump Types?

Diaphragm pumps are versatile and handle various fluids, including corrosive ones. Compared to centrifugal pumps, they handle higher viscosities and solids. They are often more energy-efficient than pneumatic pumps. However, their initial cost might be higher, but their durability often offsets this over time.

Are Diaphragm Pumps Expensive To Maintain?

Diaphragm pumps generally have low maintenance costs. They have fewer moving parts, reducing wear and tear. Routine checks and timely replacement of diaphragms can minimize costs. Their robust design contributes to longer service intervals, making them cost-effective over the pump’s lifespan.

What Is The Average Price Range For Diaphragm Pumps?

Diaphragm pumps can range from $100 to over $2,000. The price varies based on size, material, and application. Smaller, plastic models are usually less expensive, while larger, industrial-grade pumps with metal construction are pricier. Custom features and higher capacities can also increase the cost.

Conclusion

Choosing the right diaphragm pump affects your budget and performance. Consider your needs and compare features carefully. Prices vary based on materials and technology. Evaluate energy efficiency for long-term savings. Factor in maintenance costs too. Brands offer different warranties and support.

Research customer reviews for reliability insights. A thorough cost comparison helps make an informed choice. Prioritize quality and durability over just price. This ensures a pump that meets your needs effectively. Investing wisely in a diaphragm pump benefits your operations.

Remember, a well-chosen pump lasts longer and performs better.

Read More:

- Best Home Water Filtration Units: Top Picks for Clean Water

- Diy Hydroponic Grow System Guide: Cultivate Success

- Mini Hydro System Feasibility Study: Unlocking Eco Solutions

- Chemical Dosing Pump Pricing Guide: Maximize Your Investment

- Hydroelectric Dam Maintenance Cost Analysis: Cutting Costs

- Commercial Water Filtration System Cost: Save Money Today

- Diaphragm Pump Maintenance Tips: Ensure Peak Performance

- Submersible Sewage Pump Price: Affordable Options Reviewed